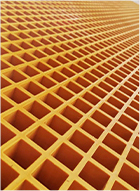

moulded gratings

Links

-

Hexagonal mesh is made of galvanized iron wire woven by automatic mesh machine, mesh into regular hexagonal shape, mesh standard, beautiful, mesh size can be customized according to customer requirements, usually 27mm,20mm, 13mm, wire diameter from 0.40mm to 1.20mm, to meet the requirements of different customers.

- 4. Rinse the foam off your cat thoroughly.

-

Decorative hook mesh selection of stainless steel, aluminum alloy, brass, copper and other alloy materials, through the special process of preparation of hook mesh. It is a silk screen made of decoration. Today we introduce the aperture and wire diameter of the decorative hook mesh.

- At present, blade barbed rope has been widely used in industrial and mining enterprises, garden apartments, border posts, military fields, prisons, detention centers, government buildings and other national security facilities in many countries.

- Take 20cm galvanized wire for acid fog experiment, check the zinc content of galvanized wire through the balance to see whether it meets the zinc layer standard required by the customer, ensure that the metal wire can achieve the role of rust and corrosion prevention, and meet the service life required by the customer. Galvanized iron wires must be packed in good condition, bound neatly and orderly, and bound with an inward end to prevent scratches during transportation. The inspection standard of galvanized iron wire also includes the tensile test. This item is determined according to the material of the galvanized wire order ordered by the customer, and it needs to be tested by comparing the raw material list.

-

Six features of spray blade stabbing rope

-

Post time: 20-09-22 - (4) granary storage, circle corn net.

-

1, pasture installation of barbed rope material electric galvanized barbed rope and hot-dip galvanized barbed rope are economical choices. The products are durable and low in price.

-

The use of bundled galvanized wire with the development of industry and agriculture also expanded accordingly. Therefore, galvanized wire products in the industry, such as chemical equipment, oil processing, Marine exploration, transport, electricity, shipbuilding, metal structure, etc.), agriculture (such as sprinkler irrigation, dim room, building (such as water and gas transport, wire casing, scaffolding, house, etc.), Bridges, shipping, etc., has been widely use in recent years. Because galvanized wire goods have beautiful surface, good corrosion resistance and other characteristics, its use scale is more and more extensive.

-

Zinc is a silver-white metal, brittle at room temperature, soluble in acid and alkali, known as amphoteric metal. Pure zinc is more stable in dry air, and small in humid air or water containing carbon dioxide and oxygen. A thin film layer of basic zinc carbonate will be formed on the surface, which can delay the corrosion rate of zinc layer. The corrosion resistance of galvanized layer in aqueous solution of acid, alkali and sodium chloride is relatively strong. It is also not resistant to corrosion in atmospheres containing carbon dioxide and hydrogen sulfide and in Marine atmospheres; In high temperature and high humidity air and containing organic acid atmosphere is small, galvanized layer is also easy to be corroded.

-

Dog cage mainly by welding, spraying, injection molding, surface treatment, electroplating dog cage is made of high quality steel wire, dog cages are with plastic and plastic surface treatment, electrophoresis, chrome plating, galvanized, imitation gold, etc., according to the customer request processing, respectively, also can be customized to sample, dog cage assembly of compact structure, neat and beautiful appearance, make folding and remove the cage is more convenient and quick, won’t take up too much space.

- How much does a spike rope weigh in a meter? In fact, after figuring out how many meters a kilogram of barbed rope, this problem will be solved, and it is OK to divide a kilogram directly by the number of meters.

- Galvanized also has several different methods, the so-called hot dip galvanizing is put racing in the zinc bath, need to clean them on metal, which ensures that formed between metal and coating adhesive, after cleaning, the matrix metal is dissolved, to clear any residual oxides of residue and then immerse the substrate metal heating liquid zinc, and metallurgical bonding is formed.

-

① The diameter of galvanized iron wire for drawing shall not be less than 4mm, and the diameter of galvanized iron wire for binding shall not be less than 2.6mm.

-

Post time: 14-06-24 -

You can also buy a cage from other places. You can choose the cage you like or find suitable on the website. For example, a pet store, supermarket, pet products website, etc., it is recommended that you buy metal cage, with a metal tray underneath, of course can also be of stainless steel and plastic, is plastic easily damaged by the dog bite, plastic tray is easy to be a dog of uric acid corrosion, but also show the low end of the plastic products, beautiful, durable.

-

Many customers often ask: a kilogram of barbed rope to less than meters? How much does a barbed rope weigh in a meter? And so on the common problems, today Haorong screen manufacturers for everyone to answer.

-

First of all: twist and reverse thorn rope durable

-

Post time: 22-02-23 -

Steel wire and iron wire have a lot of similarities, but carefully distinguish, you will find that they are not only different in the material, but also in the product characteristics are very different. So when choosing, make sure you make a clear distinction between the two. Steel wire factory introduces steel wire carbon structure steel made above, generally not galvanized, used for machinery, spring. Black and hard; Iron wire: low carbon steel (mild steel), galvanized, used for joining and wrapping. It’s white and soft.

- All can do spring can be called spring steel wire, and high carbon is the highest carbon content. Features: WITH high strength and hardness, high elastic limit and fatigue limit (especially notched fatigue limit), cutting function is OK, but welding function and cold plastic deformation ability is poor.

-

In addition, before the wire enters the zinc liquid, a layer of insulation material containing zinc oxide reducing agent can reduce the heat loss and zinc ash floating. When the zinc solution contains 0.002%-0.005% aluminum, the brightness of the zinc layer can be increased obviously, and excessive zinc ash can be prevented from oxidation on the surface of the zinc solution.

-

Stainless steel blade barbed wire production process is similar to galvanized blade barbed wire production process, usually according to the mold to determine the size of the blade.

-

Fourth, the difference between 201 and 304 is the problem of nickel. And the price of 304 is relatively expensive now, generally close to 20,000 yuan per ton, but 304 can at least ensure that it will not rust in the process of use. (Experiment with potions)

-

Galvanized iron wire is a substance we often see in life. It is the zinc gradually plated on the metal surface through the unidirectional current in the electroplating tank. The production speed is slow, the coating is uniform, the thickness is thin, usually only 3-15 microns, the appearance is bright, the corrosion resistance is poor, and the corrosion will rust in a few months. Galvanized wire has the characteristics of thick galvanized layer, strong corrosion resistance, strong galvanized layer, etc., the products are widely used in construction, highway walls, Zahua, weaving nets.

-

Some customers pay more attention to the quality problem, so they pay more attention to the service life. The barbed rope factory will generally recommend the use of high zinc barbed rope or stainless steel barbed rope.

- Twisting hexagon mesh production factory is the selection of low carbon steel silk woven, mesh structure he has corrosion resistance, high strength and ductility and so on. The diameter of steel wire can reach 2.0mm-4.0mm. The surface of steel wire is usually used for hot-dip galvanized maintenance. The thickness of galvanized maintenance layer can be made according to the needs of customers.

- Generally speaking steel does not rust easily with chromium content of 10.5%. The higher the content of chromium and nickel, the better the corrosion resistance, such as 304 material nickel content in 8-10%, chromium content of 18-20%, such stainless steel in general is not rust.

-

Post time: 23-02-23 - 2. When there are natural barriers such as canals, ponds and lakes on the side of the road, barbed rope protection nets shall not be set up in the section where there is no need to worry about people and livestock entering and illegally occupying the road land.

-

1, galvanized silk mesh molding sheet must be packed with flat hard materials, to avoid improper packaging and eternal deformation. It is important that each package and roll of raw material be marked with product name, standard, quantity, trademark, lot number, manufacturer, date of production, packing symbol, inspector code and inspection certificate.

-

From the plastic spraying, spraying blade gill net (pvc blade gill net, plastic blade gill net), also known as spraying blade barbed wire, spraying blade barbed wire is produced in the future, to rust treatment by the attack. Spray appearance treatment makes it have quite good anticorrosion ability, beautiful appearance, good waterproof effect, easy construction, economic and practical excellent characteristics. Spray blade thorn rope is a plastic powder spray on the product blade thorn rope of an appearance treatment method.

-

The common barbed rope produced by the manufacturer is the 14*14 type of barbed rope product. Since the warp wire used is the same as the wire diameter of the barbed rope, it is easier to calculate the length and weight. Usually each kilogram of barbed rope can reach about 10 meters of service length. The length of each kilogram of raw material is about 35 meters. Both 35 meters length of raw materials can produce 10 the length of the wire diameter barbed wire cost.

- wire mesh fence sizes

- 3d welded wire fence

- 4 ft black chain link fence cost

- 2 inch welded wire mesh

- 2 inch x 2 inch wire mesh

- 72 x 100 welded wire fence

- 16 gauge galvanized wire fencing

- brc weld mesh

- plastic coated tie wire

- pvc gi wire